Self-drilling screws, the modern marvels of the carpentry world, have revolutionized the way we tackle fastening projects. These versatile fasteners combine the power of drilling and screw driving into one convenient package, saving time and effort while delivering secure connections. This comprehensive guide will delve into the intricacies of using self-drilling screws, equipping you with the knowledge and skills to tackle any project with confidence.

Image: bdnfasteners.com

Understanding Self-Drilling Screws

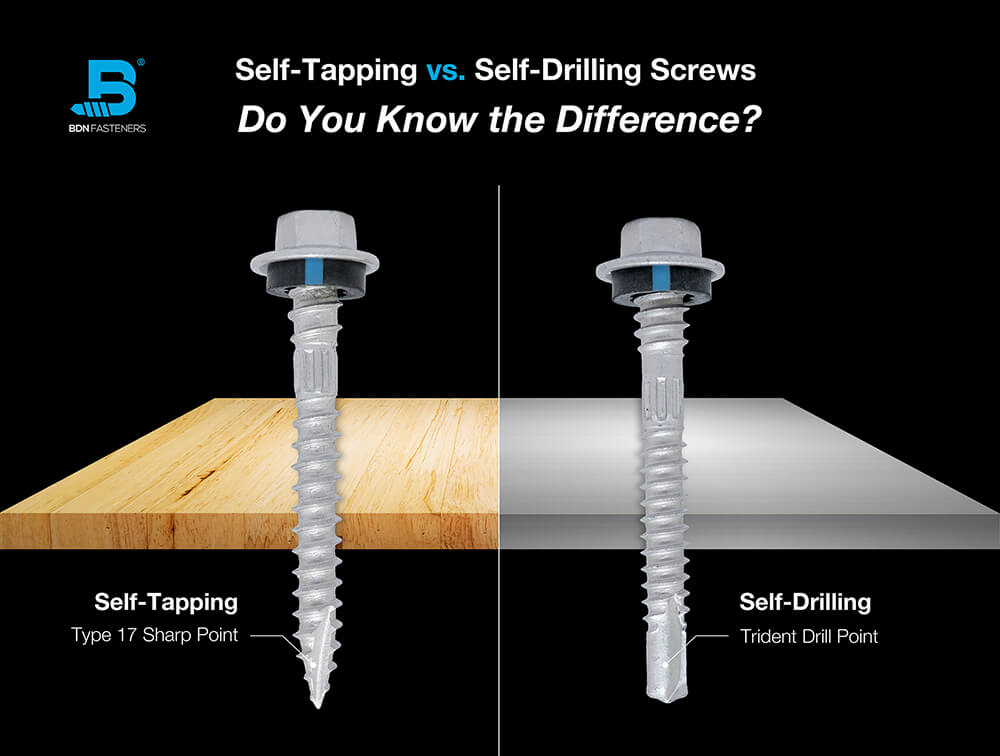

Self-drilling screws, also known as Tek screws or self-tapping screws, are specially designed with a pointed tip and aggressive threads that eliminate the need for pre-drilling pilot holes. These screws feature a sharp, triangular tip that pierces through metal, wood, and even plastic, creating its own path for the threaded portion of the screw to follow. As the screw is driven in, its threads engage with the material, forming strong and lasting connections.

The Advantages of Self-Drilling Screws

The versatility and convenience of self-drilling screws make them an indispensable tool for a wide range of applications. By combining drilling and fastening into one efficient step, these screws offer numerous advantages:

- Time-saving: Eliminating the need for pre-drilling significantly reduces project completion time, freeing up valuable hours for other tasks.

- Effortless installation: With just one tool (a drill or impact driver), you can effortlessly drive self-drilling screws without the hassle of multiple drilling and screw-driving steps.

- Cost-effectiveness: By reducing the steps involved in fastening, self-drilling screws minimize the need for additional drilling bits and specialized tools, saving you money in the long run.

- Secure connections: The combination of the sharp tip and aggressive threads ensures a strong, vibration-resistant hold, even in challenging materials.

Choosing the Right Self-Drilling Screws

Navigating the wide selection of self-drilling screws available on the market requires careful consideration of the following factors:

- Material: Self-drilling screws are designed for use in specific materials such as metal, wood, or plastic. Ensure you select screws with a tip and threads suitable for the material you are working with.

- Length: The length of the screw should be proportionate to the thickness of the materials you are fastening together. Too short a screw may not provide adequate holding power, while too long a screw could protrude through the opposite side of the workpiece.

- Diameter: The screw’s diameter affects the strength and holding power of the connection. Choose a diameter that provides sufficient strength without compromising the integrity of the materials being fastened.

- Head style: Self-drilling screws come in various head styles, such as hex, Phillips, and square driver. Select the head style that matches the driver you have available or that best suits the aesthetics of your project.

Image: automatedfastening.com

How to Use Self-Drilling Screws

Using self-drilling screws is a simple and straightforward process:

- Mark the screw hole: Align the two pieces of material to be fastened and mark the location of the screw hole.

- Align the screw: Position the self-drilling screw at the marked location and ensure it is perpendicular to the surface of the material.

- Drive the screw: Using a drill or impact driver, slowly drive the screw into the material. Apply firm but controlled pressure to avoid stripping the threads or damaging the material.

- Tighten the screw: Continue driving the screw until it is fully tightened and flush with the surface of the material. Avoid overtightening, as this could weaken the connection or damage the screw head.

How To Use Self Drilling Screws

https://youtube.com/watch?v=UAlORF3uIHM

Tips for Using Self-Drilling Screws:

- Use a variable speed drill or impact driver: This allows you to control the speed of screw driving and minimize the risk of damaging the screw or the material.

- Lubricate the screws: Applying a drop of oil or wax to the threads of the screw can help reduce friction and make driving easier.

- Use the right drill bit: For materials other than metal, consider using a twist drill bit with a diameter slightly smaller than the root diameter (the diameter at the bottom of the screw threads) to